Data Center Solutions

Precision Roll Form Fabrication Solutions That Power Next Generation Data Centers

Our Role in Data Center Infrastructure

Hyperscale data centers are at the forefront of the cloud computing revolution, propelling exponential growth in off-premise large-scale data analytics and AI solutions. These advanced data centers require specialized power distribution units (PDUs) with high-current carrying capacity busway systems, as well as robust HVAC systems equipped with secondary cooling units designed to maintain optimal temperatures for rooms, server cabinets, and semiconductor components within megawatt-scale computer racking systems.

Today's data center architectures are engineered to support high-speed, high-power CPU, GPU and DPU racking systems, necessitating precision-engineered server racking and cabinet enclosures. Modern data centers also demand stronger structural support in both ceiling and flooring solutions to ensure the highest levels of reliability, performance, and scalability.

Hynes Industries helps our Data Center customers power AI in the digital world. For over 30 years, Hynes Industries has been a trusted partner with leading Data Center product OEMs, delivering precision-engineered roll form components and custom-fabricated solutions that power the infrastructure of modern data centers. Our expertise in roll forming and utilizing new innovations in custom fabrication allow us to collaborate with our customers at a highly technical level to design and manufacture custom components and assemblies that optimize electrical performance, provide improved structural integrity, reduce material costs, eliminate secondary operations and streamline installation for mission-critical Data Center applications.

Hynes collaborates with data center equipment manufacturers, racking system providers, and general contractors to produce components for a wide range of applications, including:

- Structural components for Switch Gear and Power Distribution Units

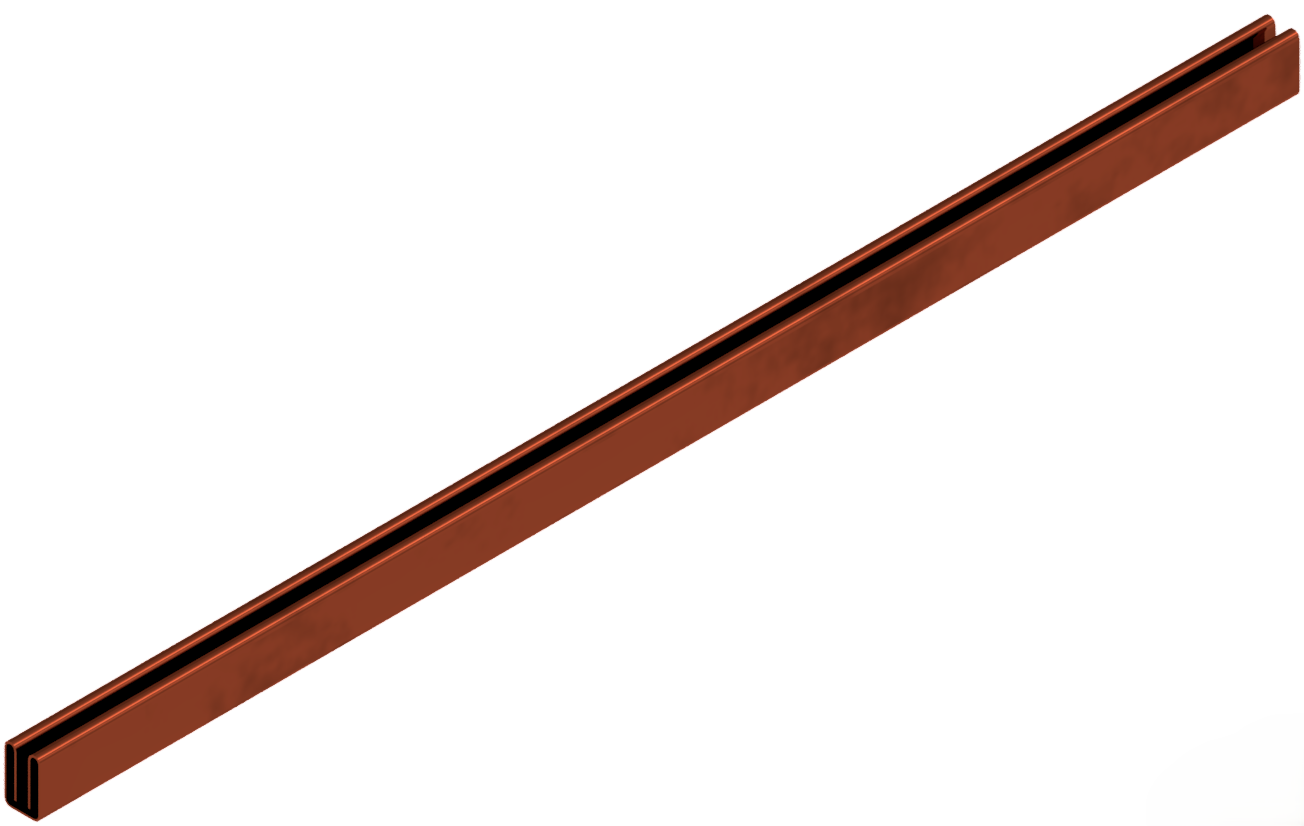

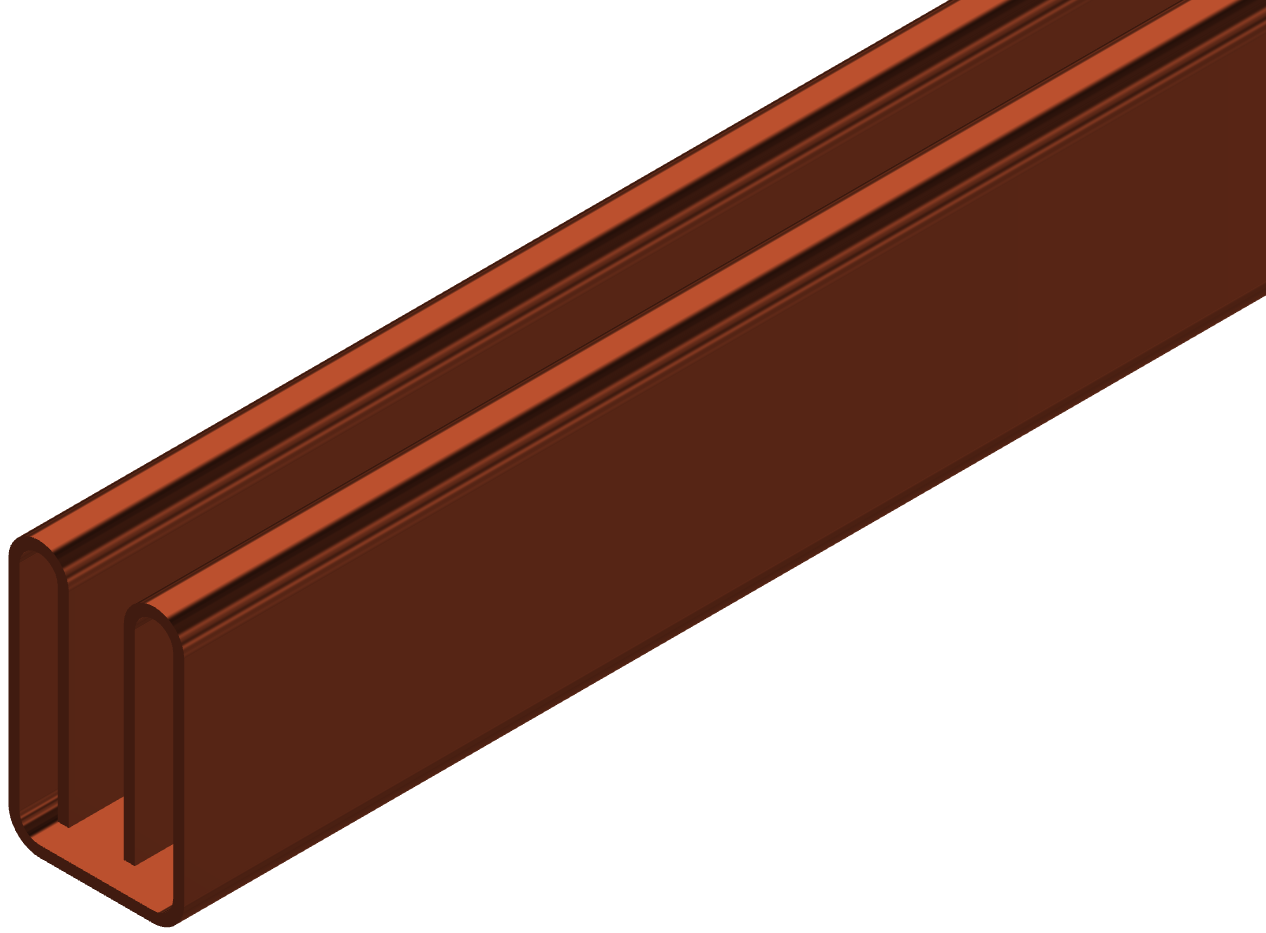

- High current-carrying Copper “M” profiles to power electrical Busways

- Server Racking and Cabinet Structural Frames

- Base Rail, Rabbets, Corner Posts, Latches and Door Panel components for electrical applications, Switchgear and electric power distribution systems

- Cable Management channels and trays

- Ceiling Structural components and Floor Stringer components

- Power Panel components including Mini-Strut, DIN Rail, Panel Supports/Stiffeners and other components

Our engineering team collaborates with your design, procurement, and installation teams to develop roll form solutions that enhance functionality, reduce weight, and lower total cost of ownership. By leveraging our advanced roll forming capabilities, we eliminate secondary processing, simplify assembly, and ensure tight tolerances to meet the rigorous demands of data center environments.

Hynes also offers tailored fulfillment programs, including just-in-time delivery, pre-stocking, and large-scale project support, to ensure your components are on-site when you need them. With more than 425,000 square feet of production and warehousing space, we provide agile, reliable solutions to keep your projects on schedule and within budget.

Server Rack and Cabinet Solutions

Hynes delivers high-strength, precision roll form profiles for server racks and cabinets. Our components are engineered to maximize load-bearing capacity while minimizing material use, ensuring robust support for servers, networking equipment, and cabling systems.

Cable and Power Management

Efficient cable and power management is critical to data center performance. Hynes produces roll form cable trays, channels, and din rail components that ensure organized, secure, and accessible wiring systems. Our profiles are designed to accommodate high-density cabling and power distribution requirements while maintaining compliance with industry standards for safety and performance.

Busway Solutions

Hynes specializes in roll forming copper profiles for busway systems, providing efficient and reliable power distribution solutions for data centers. These precision-engineered profiles offer superior conductivity, and enhanced thermal performance, optimizing power delivery while minimizing installation time and costs. Our capabilities are tailored to meet high-current demands and integrate seamlessly with existing infrastructure, ensuring scalability and reliability in high-density environments.

Select Data Center Profiles

15

Million Pounds Annually

4

Million Parts Annually

17

Million Feet Annually

30

Years of Data Center Experience

Capabilities

At Hynes, there is no limit to what we can do to help you reach your business goals. Whether you need consultation on new product development, a metal fabrication project or precision-engineered custom roll form development, our engineering team can help. You can rely on our more than 400 years of Engineering expertise with multi-process roll formed metal fabrication and robotic welding to assist you with your production needs.

No Matter What You Need, We Can Help

Our manufacturing capabilities can go a long way for your company, reducing costs and labor in OEM manufacturing and end-use installation in the process. They include:- Custom Roll Form Fabrication

- Collaborative Engineering

- New Product Onboarding

- Quality Management

- Supply Chain Management

- Inventory Management

Have questions about our capabilities? Reach out and we’ll connect you with our experts.

Get The Latest From Our Experts

Check out our blog for insights from our experienced engineering professionals.

Free Resource: The Benefits of Reshoring and Onshoring for U.S. Manufacturers

Want to learn how you can de-risk your supply chain and reevaluate costs when bringing your operations back to the United States? Download this free resource, designed to answer these pressing questions and more.

Email Us

contacthynes@hynesind.com

Call Us

800-321-9257

Career Opportunities