Solar Energy Solutions

Fabricating brilliance for solar energy.

Our Role in Solar Energy

At Hynes, we recognize that building sustainable renewable energy solutions is critical to our environment and a key component of addressing climate change. Since 2012, Hynes has been working with numerous solar racking OEMs and EPCs to design, optimize and develop solar energy racking solutions—using precision-engineered roll form fabrication techniques—to optimize strength and to minimize component cost. Hynes has extensive expertise at identifying improvements in roll form profile design to clearly improve load performance and structural integrity, while identifying opportunities to trade-off material weight and reduce cost.

As the largest solar solutions roll forming company in North America, we’ve designed, produced and delivered racking components that power over 13 gigawatts of energy for some of the largest solar energy and racking companies in the world. Our engineering team can design to your specific print and tolerances, regardless of application. We provide a broad range of roll form component solutions that support large-scale, multi-site utility power programs, including fixed-tilt ground mount and tracking systems, commercial-grade rooftop systems, and a wide array of carport and canopy solar energy solutions. We have shipped to hundreds of sites across North America, and to numerous other countries including Puerto Rico, Guam, Mexico and India.

Hynes utilizes automated in-line production techniques to adjust for the various component lengths and numerous hole patterns required to support various PV module designs. This is a huge advantage in simplifying racking design and in reducing costs, as racking OEMs need flexibility in hole pattern and component lengths to support custom projects for the solar energy solutions they support. Every design is different, yet Hynes will design a flexible solution to support the variability in racking design for our customers. This greatly eliminates secondary operations and reduces labor in the field, further improving the economics of the total cost of ownership in your customers’ solar energy solutions.

Hynes has focused our expertise in producing roll form components for four major solar racking options in the industry, including solar tracker profiles, solar carport profiles, utility rooftop profiles and fixed-tilt ground mount system profiles.

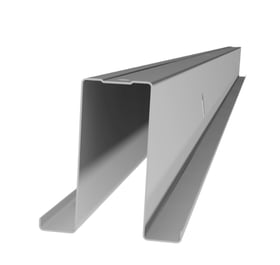

To support production, we’ve invested in press braking machines, numerous Amada Turret machines, and secondary processing capabilities to support blocking and end-cap solutions for rooftop racking profiles. Additionally, our more than 60 roll form mills allow us to quickly produce a variety of standard profiles, including Z-purlins, C-channels, box channels, strut profiles, hat channels, and several other common profiles for solar racking solutions and mounting solar panels. We also produce roll form shapes for power distribution, wire management and cable management, as well as components for battery management, stiffeners and din rail for power panels and inverter panels, and more. Hynes is your single-source for all of your racking component needs.

Solar Tracker Profiles

Our high-quality hat channels can be used across a wide variety of environments for solar tracker profiles. We also produce numerous supporting profiles to provide additional structural support, wire management, cable management, inverter and power cabinet structural profiles, and battery racking components.

Solar Carport Profiles

Designed for solar carport solutions, our L-channels, C-channels and Z-purlins are made from the highest quality steel. We have helped our customers optimize their designs by using precision in-line roll form fabrication techniques to reduce part count. We’ve also engineered designs that support multi-function end-use flexibility, reducing SKU count and labor by 40 percent. Applications include parking garages, carports, passenger train pavilions, walkways and loading areas, and more.

Utility Rooftop Profiles

Hynes has extensive experience designing custom profiles for racking providers that support utility-grade rooftop solar energy solutions. We produce numerous profiles in support of rooftop solutions, including C-channels, Z purlins, box channels, L-channels, strut and numerous custom profiles. Applications for these profiles include large-scale buildings like hospitals, manufacturing plants, large corporate buildings, schools and more.

Fixed-Tilt Ground Mount System Profiles

For more than 10 years, Hynes has supported the largest racking OEMs to design and build custom racking solutions for utility-grade installations, ranging from 5 to 10 megawatts to over 800-megawatt systems. We engineer solutions for our customers that are comprised of high-performance C channels, Z purlins and strut for fixed-tilt ground mount systems. Hynes has helped our customers identify multi-use components, where structural components can also be used for wire and cable management, greatly reducing labor and part count. Applications include utility-scale solar farms, corporate utility solar solutions and community-based utility solar solutions.

Select Solar Profiles

13

Gigawatts of Solar Racking Manufactured

10

Years of Experience in the Solar Industry

35

States Shipped to Nationwide

7

Countries Shipped to Worldwide

Capabilities

At Hynes, there's no limit to what we can do to help you reach your business goals.

No Matter What You Need, We Can Help

Our manufacturing capabilities can go a long way for your company, reducing costs and labor in OEM manufacturing and end-use installation in the process. They include:- Custom Roll Form Fabrication

- Collaborative Engineering

- New Product Onboarding

- Quality Management

- Supply Chain Management

- Inventory Management

Have questions about our capabilities? Reach out and we’ll connect you with our experts.

Get The Latest From Our Experts

Check out our blog for insights from our experienced engineering professionals.

Free Resource: The Benefits of Reshoring and Onshoring for U.S. Manufacturers

Want to learn how you can de-risk your supply chain and reevaluate costs when bringing your operations back to the United States? Download this free resource, designed to answer these pressing questions and more.

Email Us

contacthynes@hynesind.com

Call Us

800-321-9257

Career Opportunities

.

.