Collaborative Engineering

Partner with Hynes to transform the manufacturing development process using the latest design and fabrication technologies.

Our Collaborative Engineering Process

With more than 150 years of combined engineering experience, our team understands what it takes to manufacture parts efficiently and successfully. We understand that no two projects are exactly alike—from initial profile engineering to final delivery, our knowledgeable engineering and production staff will collaborate with you to develop a customized roll form fabrication solution that will yield maximum value for your product.

Our holistic approach to roll form design keeps the entire supply chain in mind, ensuring our customers’ production processes are optimized for both cost and manufacturability. We work closely with our talented team and qualified vendors to ensure that we are integrating the highest level of design foresight, technical support, quality and service. Our engineering team engages up-front with our customers and is involved throughout the entire project—from design through production—keeping our customers educated, updated and informed on a regular basis. We want to be your long-term partner for success, and working together is the only way to succeed.

Metal Fabrication Engineering Services

Whether you need consultation on new product development, a metal fabrication project or precision-engineered custom roll form development, our engineering team can help. Rely on our expertise in multi-process roll formed metal fabrication projects. We specialize in the following technical capabilities:

- Conceptual and concurrent roll form and metal fabrication engineering

- Design for manufacturing and assembly

- Engineering project management

- New product concept design, development and on-boarding

- Proactive part analysis

- Product design

- Rapid prototyping

- Tooling design

As your engineering partner, we can also help:

- Conduct rapid prototyping for simulation, tolerance and field tests

- Design for the manufacturing and assembly of complex linear shapes

- Manage tooling design

- Provide proactive part analysis to uncover design flaws

- Redesign products to optimize for roll forming while maintaining structural integrity

Our engineering and design services are also complemented by prototyping, quality management, tooling cost and budgeting, complete new product onboarding and ongoing inventory management to optimize fulfillment.

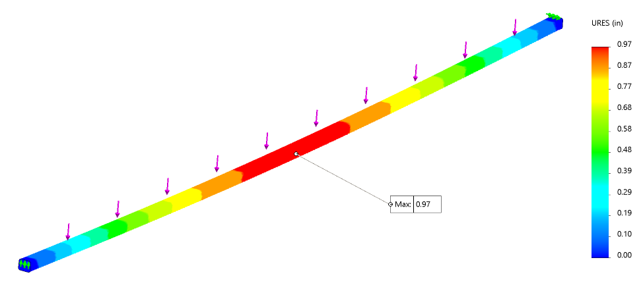

Proactive Part Analysis

Hynes does far more than manufacture the same part over and over again. As part of our manufacturing and engineering solution, we provide a proactive part analysis where we evaluate the application and design before production begins. During this type of evaluation, we assess opportunities to reduce cost and optimize design for manufacturability.

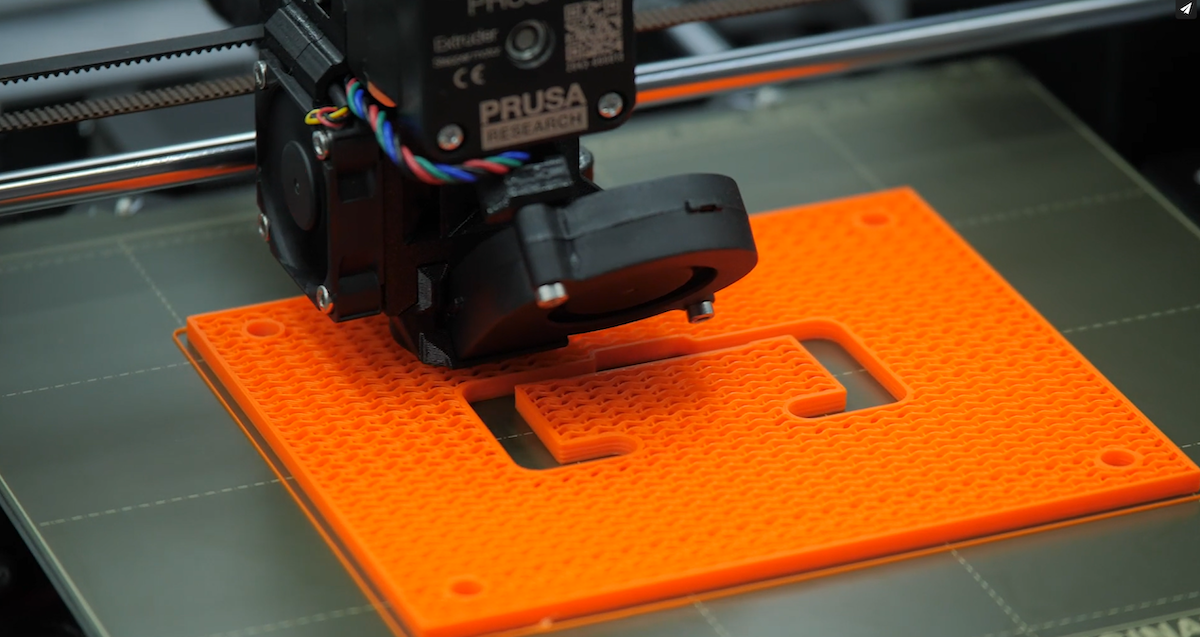

Our engineering team can also create 3D models of profiles for further assessment of design and end-use. We use additive manufacturing as part of our own evaluation to compliment and improve our own production and fabrication processes. Learn more out about our 3D printing capabilities here. (Link to 3D Printing below)

From consulting on product development to full project management, our engineering team analyzes every aspect of the fabricated part, its interaction with other parts, and its assembly and function. We help you improve a product’s design and assembly efficiency, with the ultimate goal of reducing your manufactured cost.

Conceptual Engineering

Conceptual engineering is a crucial element in a project’s discovery phase. Whether changing material, minimizing assembly costs or reducing overall product weight, conceptual engineering has the potential to cut costs throughout the supply chain. Our engineering team works with you to identify the most efficient manufacturing processes, as well as reduce transportation and material expenses. We can help improve your product and save money—while never sacrificing quality.

Product Design

Designing products for roll forming presents new opportunities and nuances compared to other production methods. To yield the full benefit of roll forming in-line processing, you need an expert partner to guide you through the entire product development cycle and push the boundaries of engineering possibilities.

Our experienced engineering team identifies unnecessary aspects of a product that increase cost and cause design complexity. By taking the time to re-evaluate your existing part or design a new product optimized for roll forming, we can reduce manufacturing costs, improve lead times and decrease shipping costs while still improving efficiency and product quality.

Prototyping

As manufacturing tolerances and production processes become more complex and the per piece cost of tooling becomes more significant, it is critical to partner with an experienced roll form fabricator that can get prototyping right the first time around. As your engineering partner, we make sure parts and processes work as intended before you invest in tooling. Prototypes are provided for field testing to ensure parts fit and provide the necessary form and function as intended within the end product.

We produce prototypes using a combination of press braking, turret punching and soft roll formed tooling, which allows us to perfect product design, shorten lead times and reduce cost per piece. We also work actively with highly experienced roll form tooling experts to speed development and reduce tooling lead times to get you to market as fast as possible.

3D Printing

We’re also highly experienced with 3D printing and additive manufacturing processes. These cutting-edge technologies allow us to produce real-world samples of parts for evaluation before we need to invest in tooling to produce them. Lead times are virtually non-existent and there is no investment in general tooling. Our 3D printing capability enables us to help you get products to market faster with higher functionality, streamline our manufacturing process and cut development costs while meeting tight deadlines.

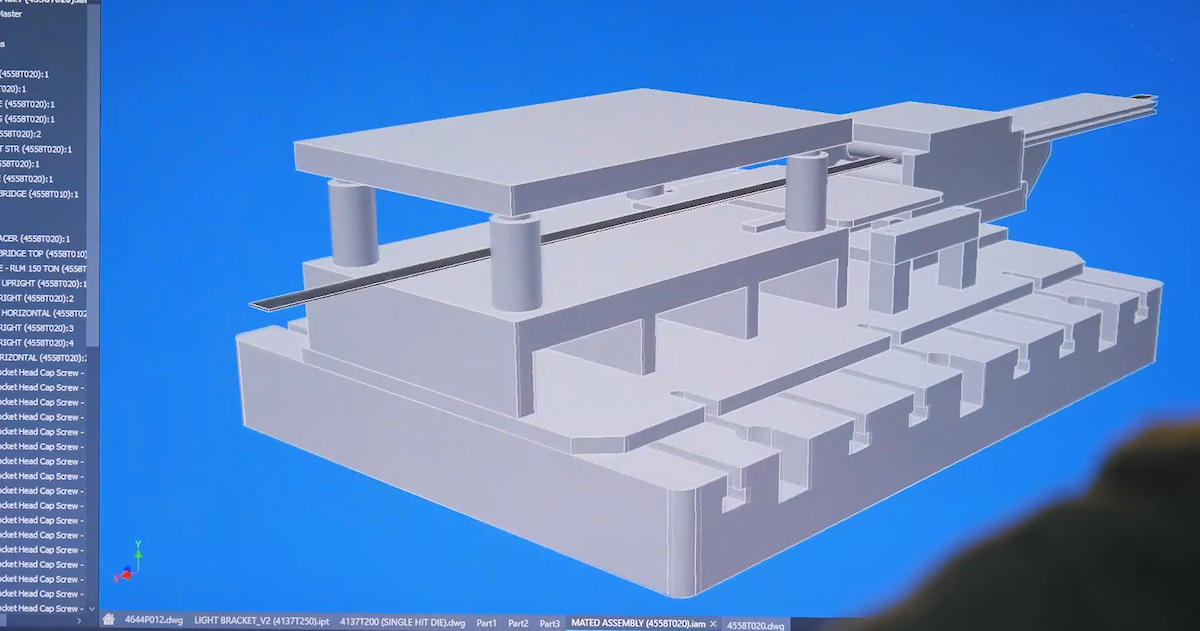

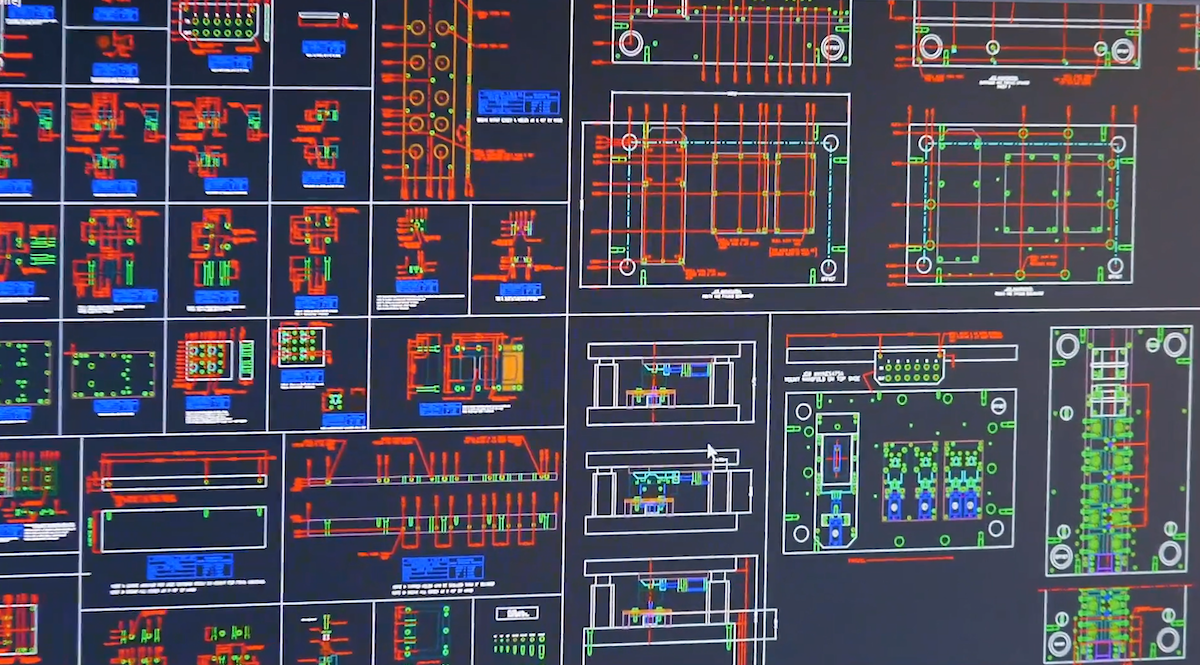

Tool & Die Design

With decades of tool and die design experience, we’re equipped to deliver the exact product you need. Our in-house tooling and die eliminates design fees and expedites development time for production. We have developed hundreds of custom dies that provide thousands of dynamic configurations, which allow single dies to be multi-configurable. For custom shapes, we can engineer tooling that can be adjusted for varying part lengths and hole patterns, speeding setup and changeover times, which reduces your production costs.

On those occasions when we require more complicated tool and die design, we work closely with highly experienced tooling vendors to develop and produce tooling in the most efficient and cost-effective way possible. No matter the project, we’re involved every step of the way in the design, from concept to procuring and tryout of the tooling, to production and fulfillment.

Customer Collaboration

At Hynes, our goal is to meet and exceed your design and production needs, which is why we keep our customers informed and involved throughout the entire project. We aim to be as transparent as possible, from our initial kick-off meeting to the tooling tryout phase, to production of first articles, quality reviews and approvals, to first production shipment. We work tirelessly to make sure our customers’ timelines are followed and that their goals are met, scheduling weekly meetings to make sure everyone is on the same page. As part of our 360-degree design and production methodology, we proactively follow up with our customers to solicit feedback on their experiences with the functionality of the part in their manufacturing process—and we use their insights to refine and perfect our processes. Hynes is your ultimate partner for roll form and metal fabrication.

Related Services

Get The Latest From Our Experts

Check out our blog for insights from our experienced engineering professionals.

Contact a Sales Engineer

contacthynes@hynesind.com

Submit an RFQ