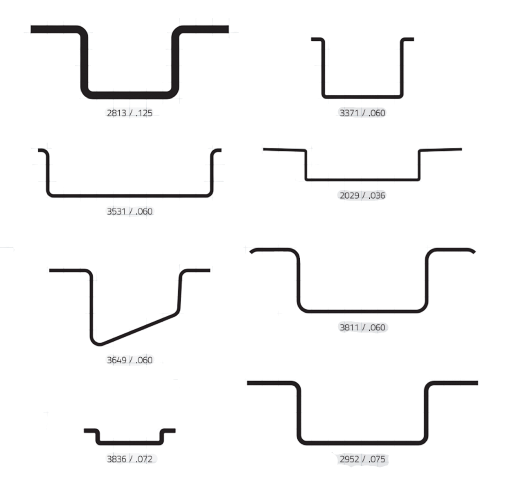

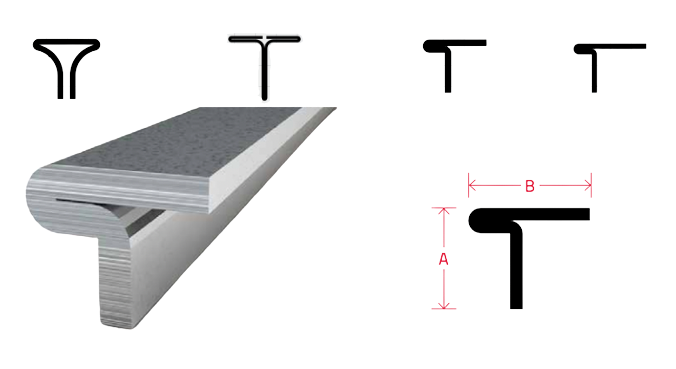

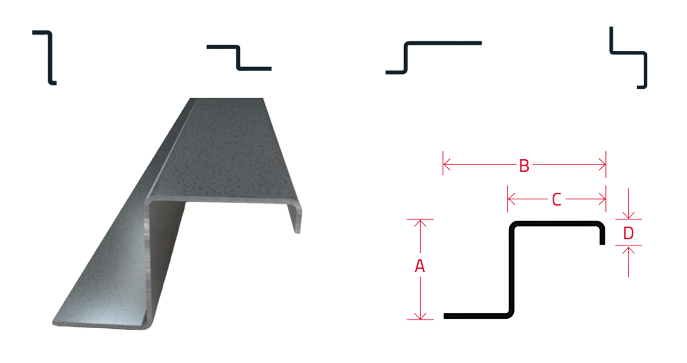

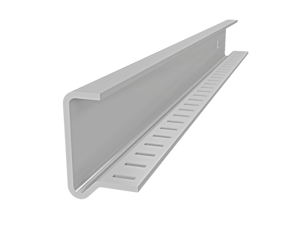

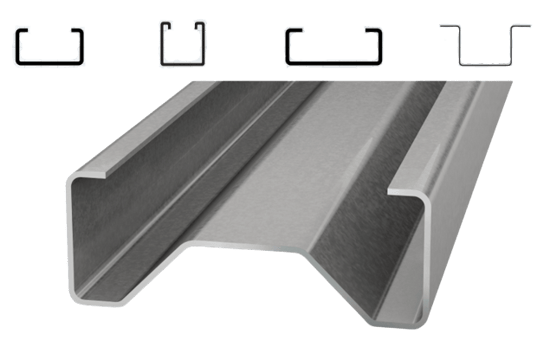

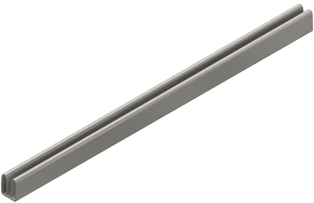

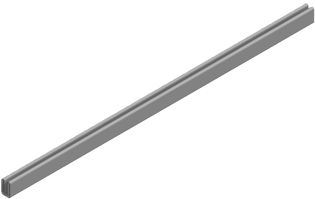

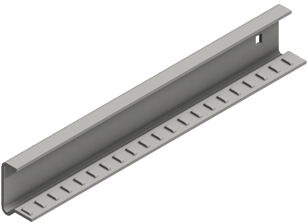

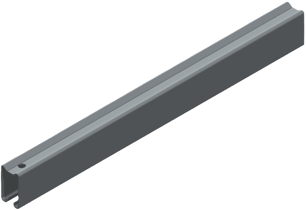

Our Custom Roll Formed Shapes

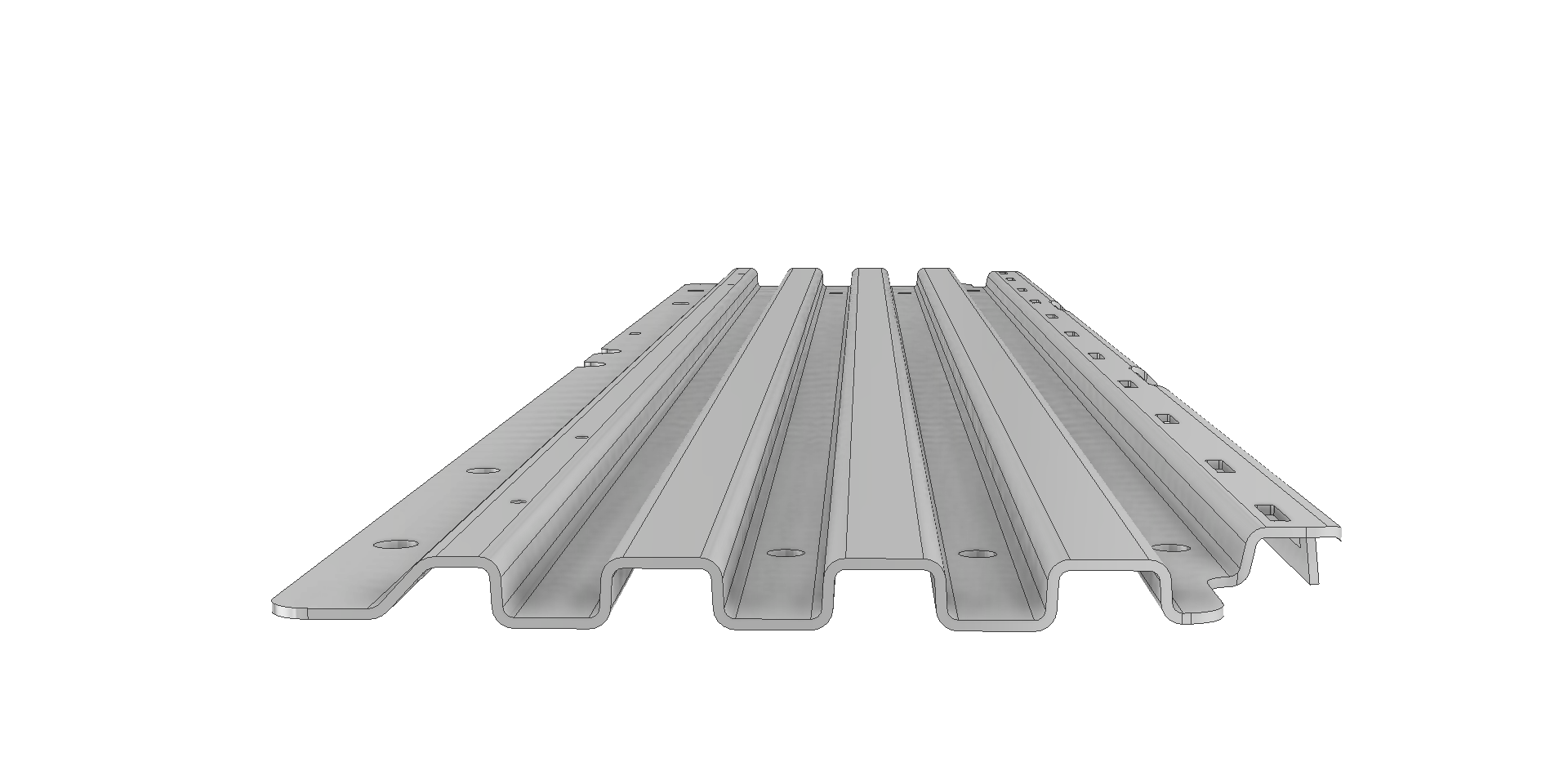

Hynes began roll forming steel products in the 1930s and custom roll form fabrication is our sole focus today.

We are the largest custom roll form fabricator in North America. Our roll formed shapes are engineered to meet the most demanding specifications of our customers. Our decades of design experience translate into an unmatched ability to offer the most functional and cost-effective roll formed solutions in the industry.

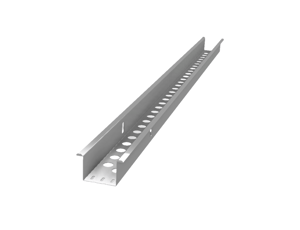

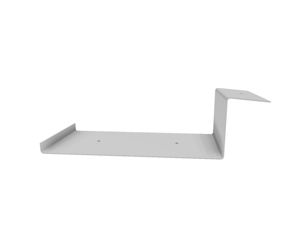

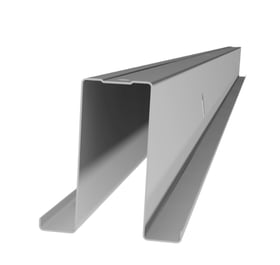

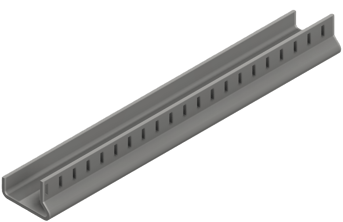

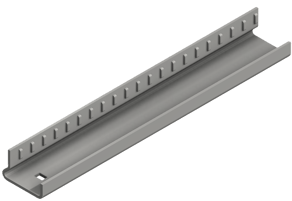

Our primary goals are to help our customers streamline manufacturability through functional design, reduce costs by eliminating secondary operations and optimize the material choices for their application. Hynes operates in three plant locations with a combined 60 automated roll forming lines. Many of our roll form fabrication lines have specialized pre-notch and post-notch capabilities to put features (holes, slots, embosses and numerous other features) into the steel before and after the roll form process, to improve manufacturability and end-use assembly. More importantly, having these capabilities can eliminate secondary operations once you receive your parts.

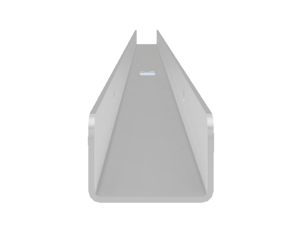

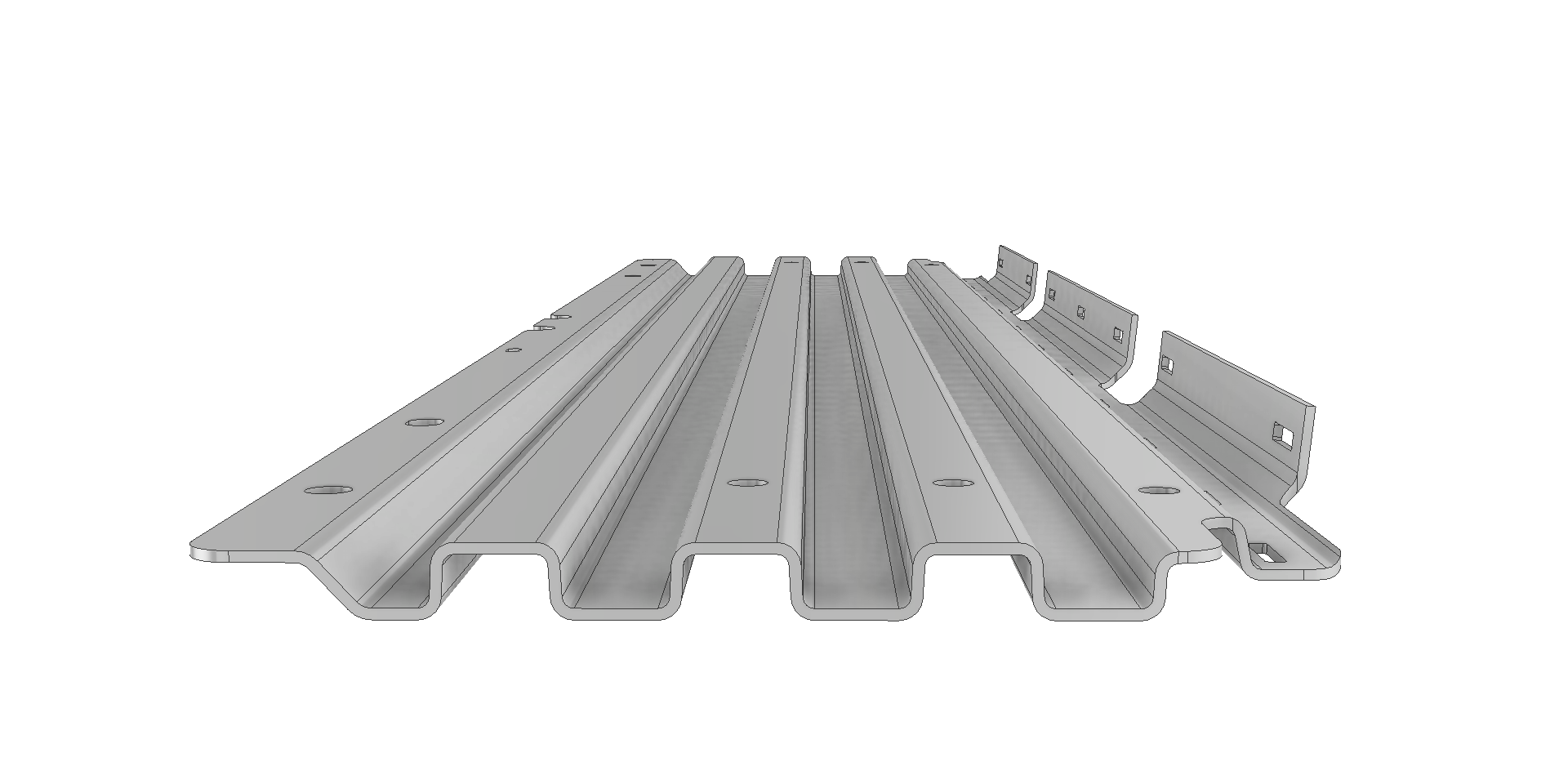

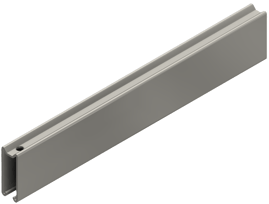

With over 500 combined years of roll forming engineering talent, we work closely with your team to design the most appropriate and economic roll form fabrication shape and production process for your application. We will help you determine the ideal material specifications for your design to optimize weight/strength trade-offs, as well as maximize sourcing and manufacturability. If secondary operations must be performed, or if you require a prototype to further assess your designs, Hynes has numerous secondary capabilities including turret punch/presses, press brakes, robotic welding and several other secondary press capabilities. We also work with various partners that provide painting, powder coating, stamping, welding, laser cutting and more.

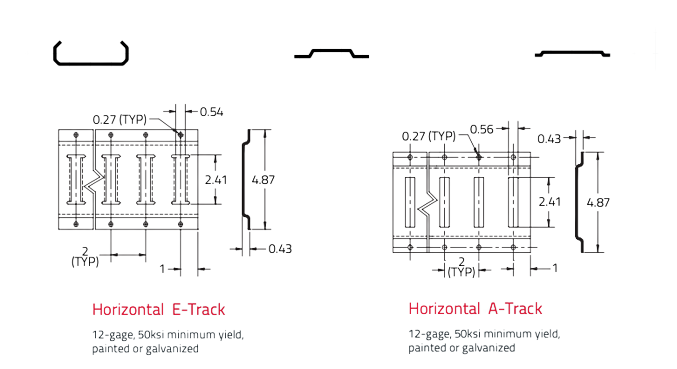

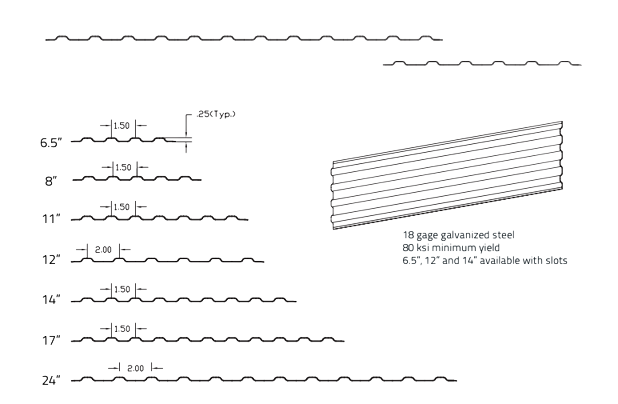

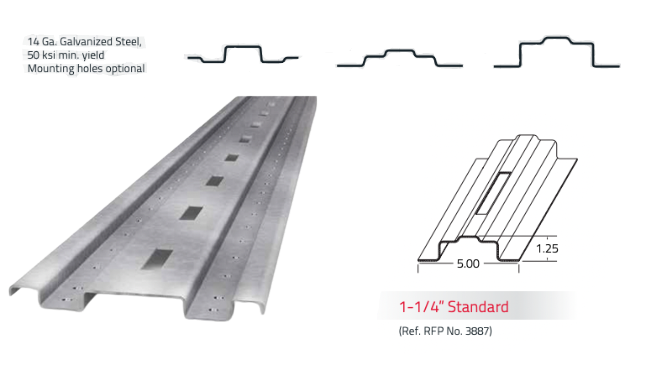

So whether you require a custom roll form shape or select a standard shape from our extensive open tooling library, we can help you design exactly what you need and ensure that you get it when you need it—on time, every time.

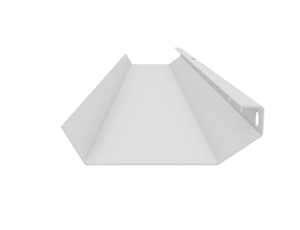

Why work with us? Check out a few reasons:

- Exceptional order response and on-time delivery performance

- Unsurpassed design and engineering talent and experience

- 60+ automated lines with in-line piercing, punching and stamping capabilities

- Full range of secondary capabilities—punching, stamping and assembly

- ISO certified quality system and 100 percent product traceability

- Competitive pricing for consistent value

- Comprehensive in-house tool & die department

- Customized packaging and logistics support

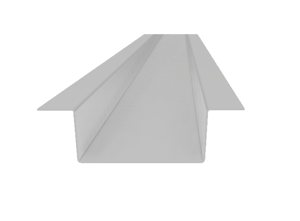

Some of our typical roll forming markets and applications include:

- Appliance

- Electrical Power Panels & Power Distribution

- HVAC Systems

- Truck & Trailer, Final Mile and Trailer Aftermarket

- Door & Window Frames and Support Hardware

- Lawn & Garden Equipment

- Commercial Building Materials

- Furnishings & Fixtures

- Food Service Equipment

- Heavy Transportation

- Construction & Mining Equipment

- Agricultural Equipment

- Solar & Wind Systems

- Material Handling & Racking Systems

- Warehouse Automation

- Vertical Farming